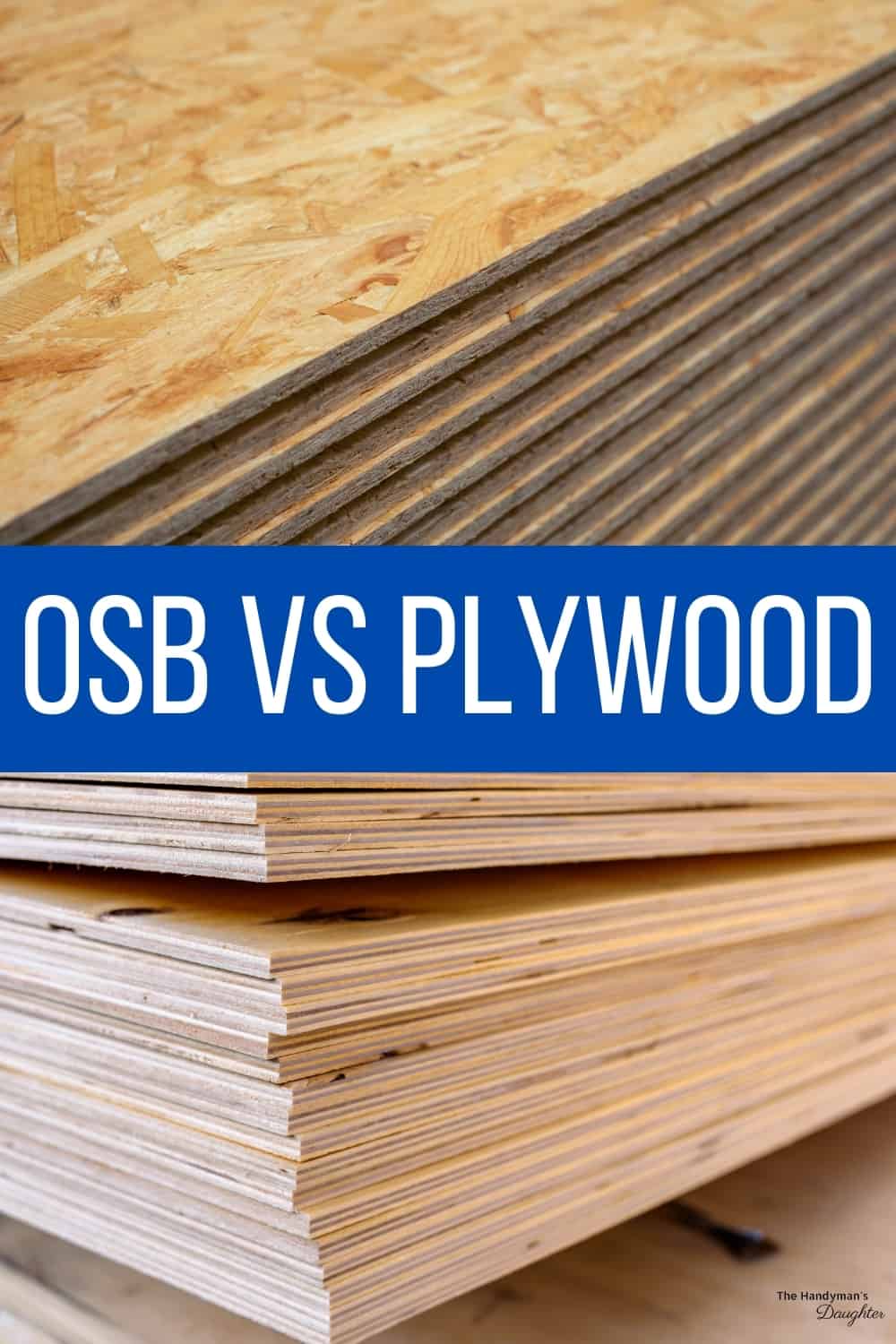

Osb and plywood are both popular materials for shelving projects. Osb (oriented strand board) is a type of engineered wood made from thin strands or flakes of wood that have been compressed with glue to form a strong, solid panel. Plywood is also an engineered product made from layers of veneer glued together in alternating directions to form a strong panel.

When it comes to shelves, osb has advantages over plywood such as cost, strength and weight-bearing capacity. Osb tends to be cheaper than plywood and can hold more weight per square foot when properly installed. It may also be easier to work with due its larger size compared to typical sized sheets of plywood – making it suitable for large shelving projects like garage storage systems or commercial displays.

On the other hand, plywood offers greater resistance against moisture damage which makes it better suited for areas where there could potentially be water exposure such as outdoor sheds or bathrooms. It’s also not prone to warping or cupping like osb so it’s often preferred by professionals for cabinet construction and furniture pieces requiring high quality finished surfaces .

In conclusion, osb vs plywood will depend on your specific project requirements – whether you need a stronger shelf at lower costs, superior finishing qualities or improved moisture protection -so make sure you consider all factors before purchasing either material!

Which is better, OSB or Plywood?

When it comes to making shelves, both OSB (oriented strand board) and plywood are strong contenders. OSB has a slightly higher strength-to-weight ratio than plywood, which makes it the better choice for larger shelving units that require extra support. Plywood is more cost effective and can be easier to find at home improvement stores.

Ultimately, choosing between OSB and plywood for shelves depends on personal preference as well as the size of the shelf project you’re working on. Both materials offer excellent stability and durability so either one could easily work in your space!

Osb Vs Plywood Price

When it comes to price, Osb (Oriented Strand Board) and Plywood are similar in cost. However, when it comes to quality, plywood is generally considered superior and may be a bit more expensive than osb. Ultimately the choice of which material to use will depend on your budget and the project you’re working on.

7/16 Osb for Shelving

7/16” OSB (Oriented Strand Board) is an economical and versatile material for shelving. It is made from wood strands that are oriented in different directions and then bonded together with resin under high heat and pressure. This makes it stronger than plywood, so it can support heavier loads without sagging or bending.

The thin profile of 7/16” OSB also allows for more storage space on shelves, making it great for creating large shelving units. Additionally, the smooth surface of 7/16” OSB works well with most paints or finishes so you can customize your shelves to fit any decorating style!

What is Osb Plywood Used for

Osb plywood is a versatile material that can be used for everything from roofing and flooring to furniture-making. It is made up of layers of thin, strong wood strands that are bonded together with adhesives to form a panel. Osb plywood has many advantages over other types of lumber because it is stronger, more resistant to water damage, lighter in weight and cheaper than traditional solid lumber boards.

Its strength makes it well suited for use as an underlayment when installing tile or hardwood floors as well as various construction projects such as walls, roofs and decks.

Osb Vs Plywood Strength

When it comes to strength, OSB (Oriented Strand Board) and Plywood are equal. Both types of wood are strong, but each has its own unique properties that make them better suited for specific applications. OSB is less expensive than plywood and can be used in structural applications where stiffness is more important than surface quality, while plywood offers a smooth finish and is often used in furniture making or interior finishes.

Osb Vs Plywood for Roofing

When it comes to roofing, there are several materials available for use. Two of the most popular choices are OSB (Oriented Strand Board) and Plywood. Both offer great structural strength and stability when used as a roof decking material, however they have some differences that may make one preferable over the other in certain situations.

OSB is typically cheaper than plywood due to its manufacturing process which involves compressing wood fibers together with resin glue. It also offers additional water resistance compared to plywood, making it ideal for areas prone to moisture damage or those located in climates where humidity levels tend to be higher throughout the year. Plywood on the other hand can provide more aesthetic appeal, but requires additional treatments such as waterproof coatings or sealants if exposed to high amounts of moisture or extreme weather conditions since it is not naturally resistant like OSB is.

Osb Vs Plywood for Flooring

OSB and plywood are both popular options when it comes to flooring materials. OSB (oriented strand board) is composed of layers of wood strands that are arranged in cross-laminated layers and bonded with wax and resin adhesives. Plywood is made from thin sheets of veneer that have been glued together at right angles for strength, making it a more lightweight option than OSB.

Both types of material offer good stability and durability, but OSB tends to be less expensive and can handle more moisture than plywood. However, plywood provides better insulation value, which makes it the preferred choice for some applications such as underfloor heating systems.

Osb Vs Plywood Water Resistant

Osb and plywood are both great materials for use in water-resistant applications. Osb is made from wood chips that have been heated, pressed, and glued together to form a strong material with good moisture resistance. Plywood is composed of thin layers of wood veneer that are cross-laminated and held together using adhesives; the layers provide additional strength and stability while also providing excellent water resistance.

Both materials can be used in wet environments but plywood offers better protection against moisture penetration than osb does.

Credit: www.thehandymansdaughter.com

Is Osb Stronger Than Plywood for Shelves?

When it comes to choosing the right material for building shelves, OSB (oriented strand board) and plywood are two of the most popular options. But which one is stronger? To answer this question, we have to look at their individual strengths and weaknesses.

OSB has a higher density than plywood, making it more resistant to impacts and heavier loads. This makes it an ideal choice for applications like shelving that require extra strength and rigidity. Plywood, on the other hand, has greater tensile strength than OSB but is less rigid overall.

Its layered construction also provides greater stability against warping or splitting over time due to moisture changes in the environment. Ultimately, if you need maximum strength for your shelves then OSB is likely your best option as its high density will better support heavier items without compromising structural integrity over time; however if you’re looking for a less permanent solution with some flexibility then plywood may be preferable due to its increased ability to resist warping or splitting under certain conditions.

Is Osb Good for Storage Shelves?

OSB, or oriented strand board, is a popular choice for storage shelving due to its durability and low cost. OSB is made out of wood strands mixed with adhesives that are compressed and bonded together in layers. This makes it strong enough to hold up against heavy items like tools, books, canned goods and more without warping or sagging.

The material also has great fire resistance which provides extra peace of mind when storing combustible materials such as paint cans or gasoline containers. Additionally, because it’s not hardwood like plywood or particleboard, OSB won’t attract pests like termites or carpenter ants either. It’s also easy to cut and drill into so you can customize your shelves however you’d like.

All around, OSB makes an excellent option for those needing budget-friendly storage shelves that will stand the test of time!

Why Use Plywood Instead of Osb?

Plywood is a popular choice for many construction projects due to its strength, durability, and versatility. It is made from thin sheets of wood bonded together in layers which makes it much stronger than other types of wood-based paneling such as OSB (Oriented Strand Board). Plywood also has superior moisture resistance when compared to OSB, making it perfect for applications such as roof sheathing and subflooring.

Additionally, plywood is easier to work with since it can be cut into various shapes without compromising its structural integrity. As a result, plywood is often the preferred material for furniture making and home improvement projects where precise cuts are necessary. Furthermore, due to its superior water resistance properties new treatments have been developed that make this type of paneling suitable even in wetter environments like bathrooms or kitchens.

All these factors combine to make plywood the ideal material when looking for something strong yet versatile enough for any kind of construction project!

Does Osb Or Plywood Sag More?

When it comes to comparing OSB and plywood, one of the most important aspects to consider is how much they sag. Although both materials can be used for a variety of applications, including flooring, roof sheathing and wall paneling, there are differences in the way each material behaves under load. OSB (Oriented Strand Board) consists of wood strands that are hot-pressed together with resin or wax binders into large boards.

Plywood is made from thin layers of wood veneer glued together in an alternating direction pattern with strong adhesives. Generally speaking, plywood will tend to hold its shape better than OSB when placed under load or stress due to its construction method. This means that it’s less likely to sag over time compared to OSB which has more flexibility as the adhesive between layers may eventually fail over time causing sagging at joints or edges.

However, this does not mean that OSB cannot be used for applications where strength and stability are required; simply adding additional support through nailing/screwing should reduce any potential sagging issues significantly.

Conclusion

Overall, it is clear that both OSB and plywood are viable options when it comes to creating shelves. While OSB may be more affordable in the short-term, plywood offers greater longevity and better performance in humid conditions, making it a more reliable choice for those looking for long-term shelving solutions. Ultimately, the decision between the two should come down to personal preferences and budget considerations.

Hello there, I’m Jim, the proud founder of Master The Wood. Woodworking is not just a hobby for me; it’s my ultimate passion. In my cozy little workshop at home, I bring my creative ideas to life, all connected to the world of woodworking.